Steps of Manufacturing DDS Burs

Steps of Manufacturing DDS Burs

Our Milling Burs could be applied to Zirconia blocks, glass ceramic, PMMA and metal.

There are 7 steps for manufacturing DDS Burs:

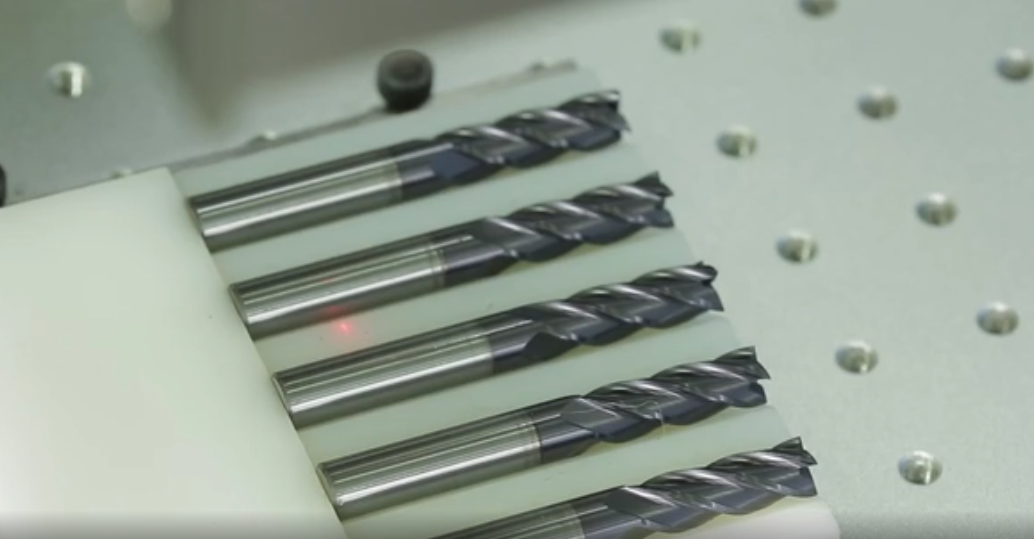

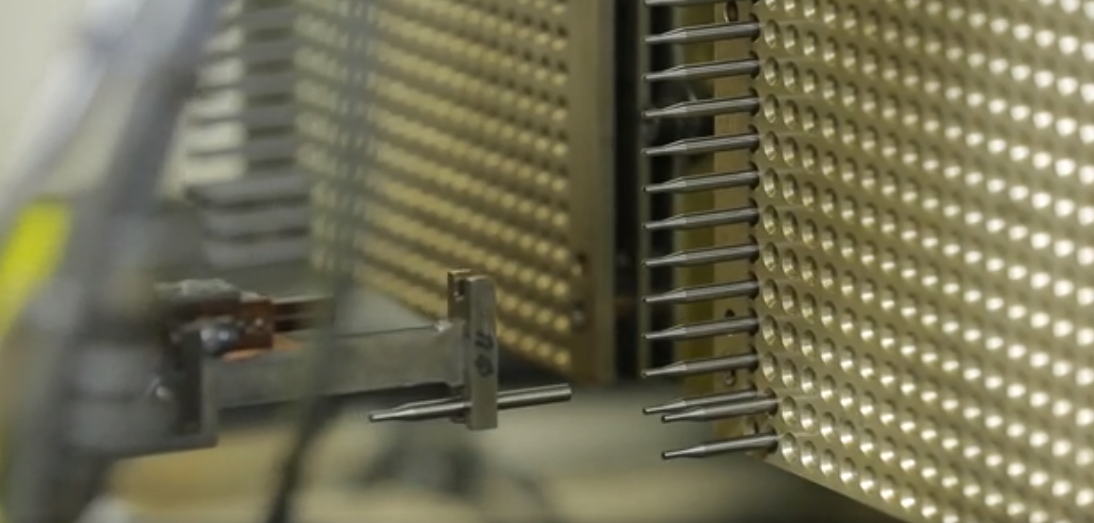

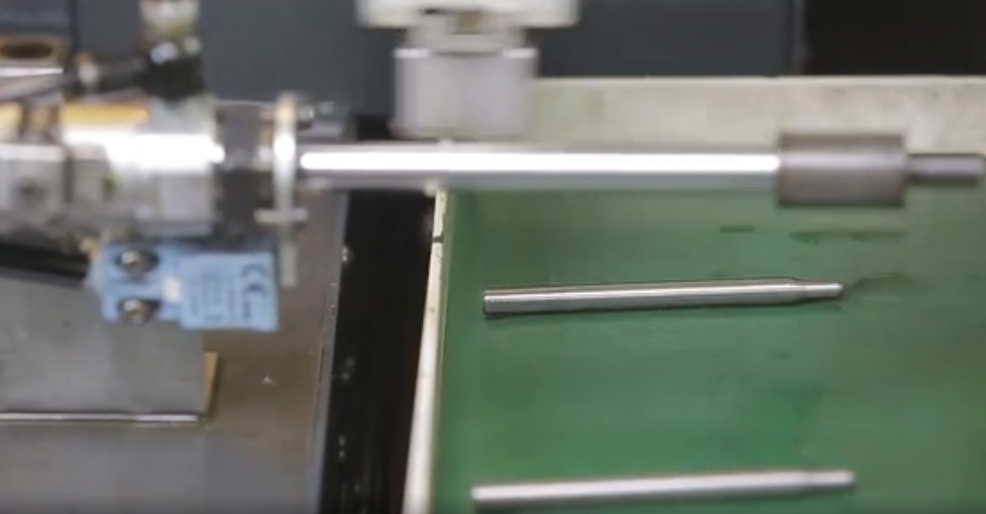

End mill pre-process

The end mill pre-process directly influences the quality of end mill, thus the polished tod needs to be processed into a ball nose, step or other formed semi-finished products.

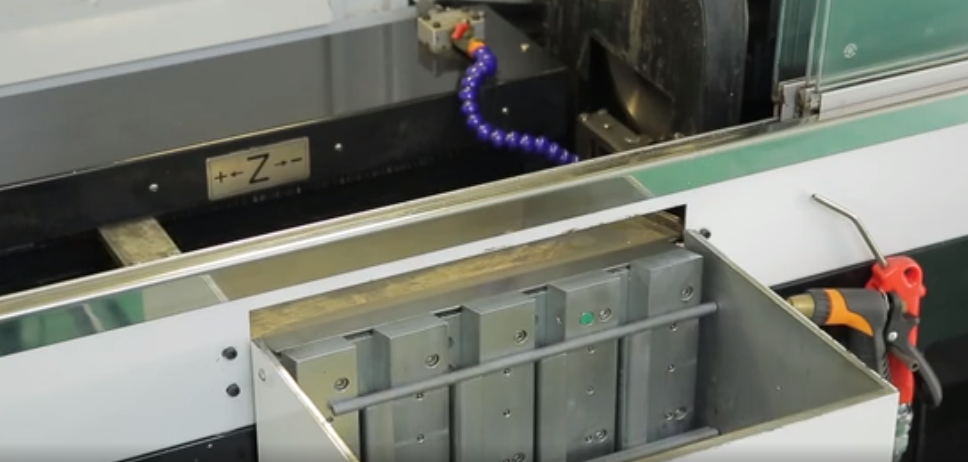

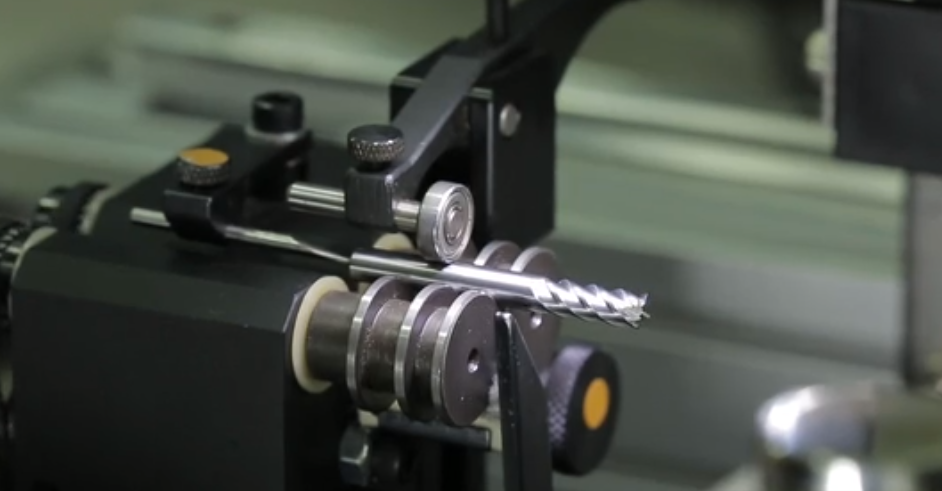

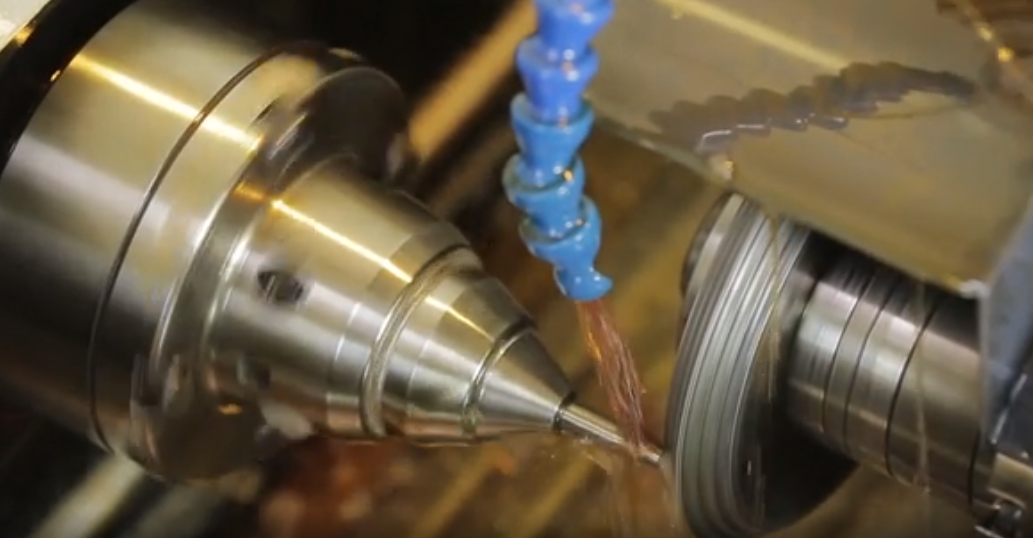

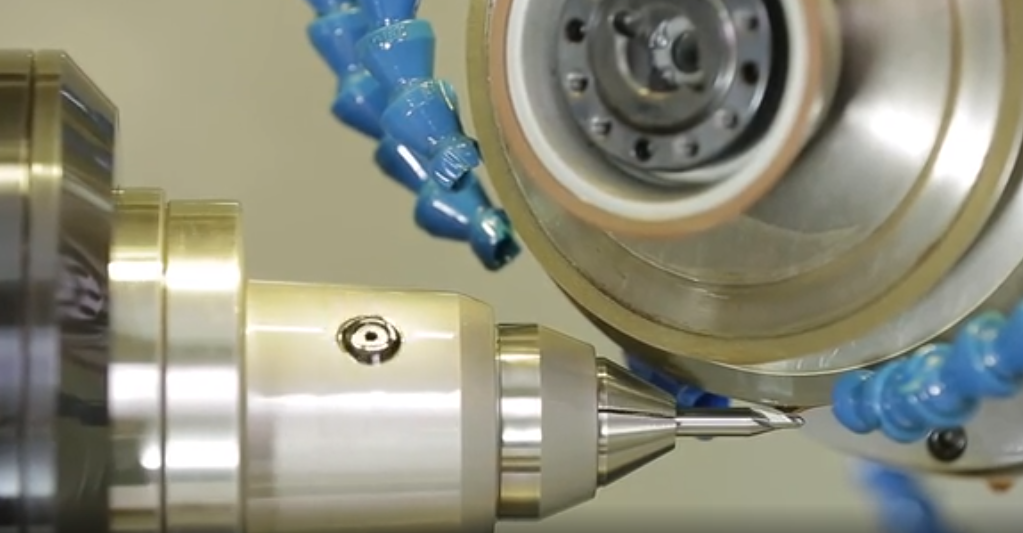

End mill grinding process

Diamond Dental Supply “DDS” has adopted high precision CNC grinding equipment imported from Switzerland, Germany, and Australia. To ensure maximum accuracy, computer numerical controls are used during the entire grinding process. The minimum radius of the end product is 0.1mm, the maximum is up to 100mm. DDS is capable of grinding any profile end mill, with an accuracy to within 0.02mm.

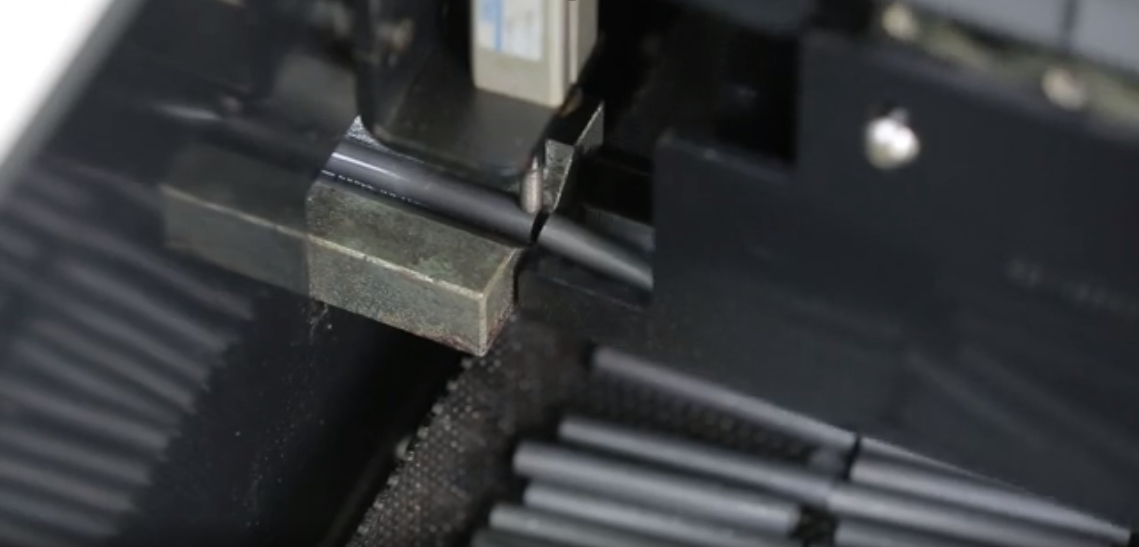

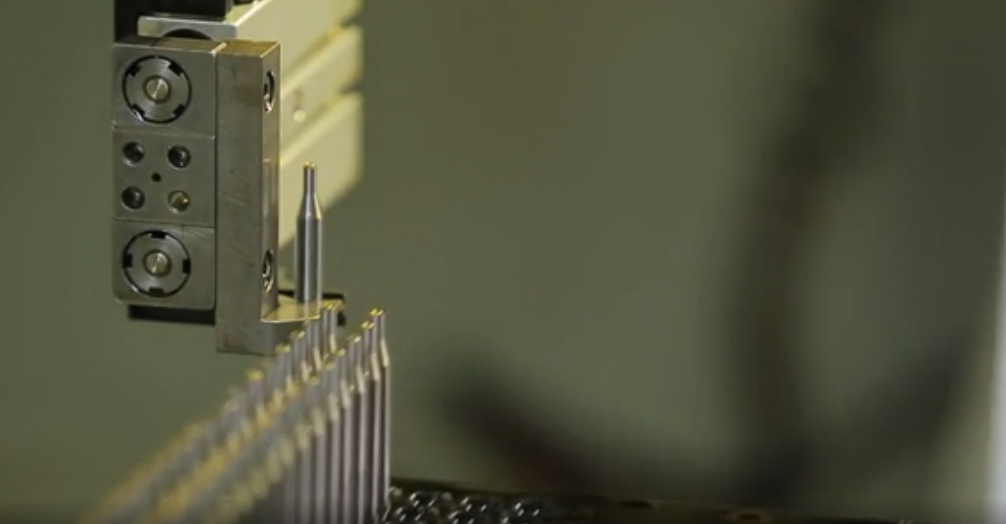

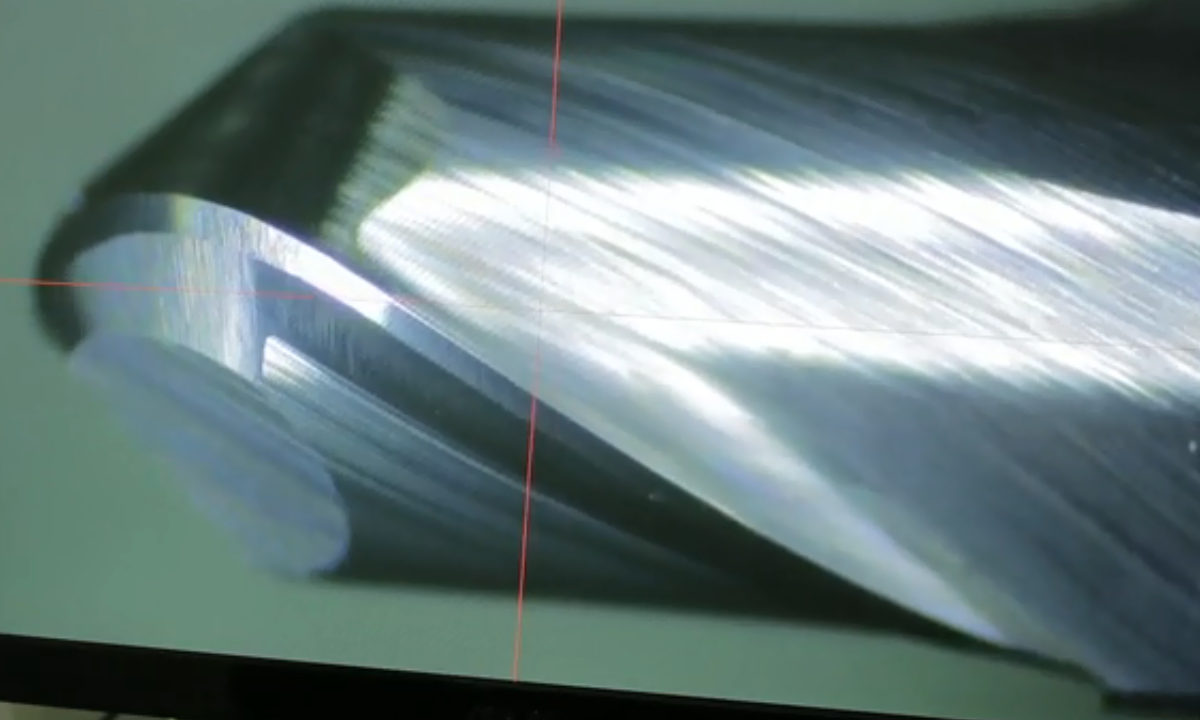

Accuracy measurement

Diamond Dental Supply “DDS” has a firm grip on total quality, using Zoller measuring instrument from Germany to monitor the measuring process with Pilot NC system software, and Delta measuring program to determine whether the end mills are confirmed to preset standards or not. In addition, the central height of the measuring module of Zoller allows the inspector to learn the damage and wear conditions of the end mills through a special lighting and image processing system, and handle the products timely and rapidly. This enables DDS to have maximum control of the quality management of our products, thereby offering flawless products to our clinets.

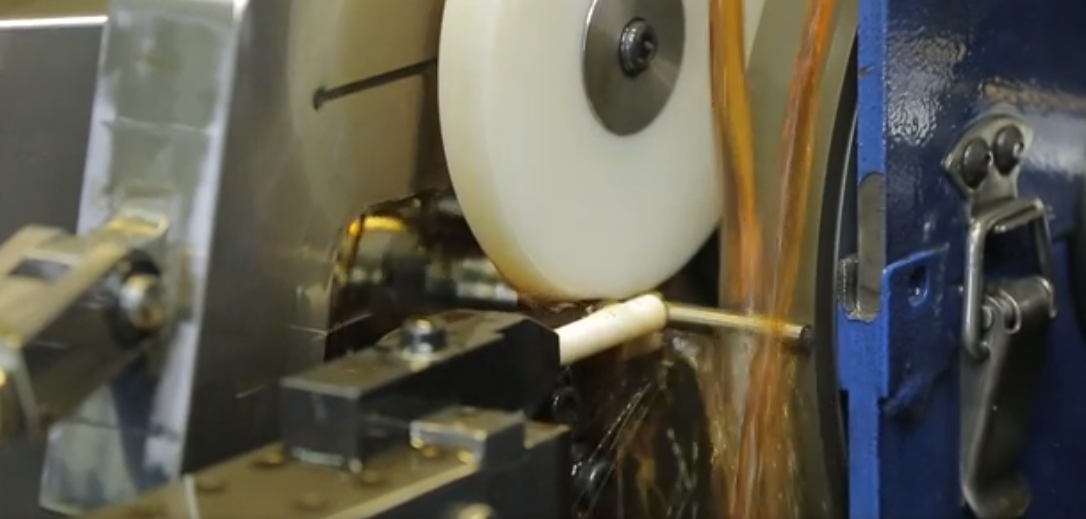

Laser Engraving

Once the end mill is approved by the DDS quality inspection department, quality control personnel will re confirm the product is intact, and then engrave model number and specifications on the produced end mills. The DDS logo will also be engraved to show our most creadible guarantee.